Chromate Conversion: The Trusted Solution for Aluminum Corrosion Protection

Chromate Conversion is a highly effective and versatile process for protecting aluminum and aluminum alloys from corrosion. Widely used across industries, it enhances the durability and longevity of metal components while delivering essential protective and functional benefits.

Key Advantages of Chromate Conversion

- Corrosion Protection for Painted or Unpainted Parts

Chromate Conversion provides exceptional corrosion resistance, whether components are painted or unpainted. It also creates an excellent base for paints and other coatings, improving adhesion and ensuring long-lasting durability. - Corrosion Protection with Electrical Resistance

For applications requiring minimal electrical resistance, Chromate Conversion is an ideal choice. It protects electrical and electronic components without compromising functionality, making it a go-to solution in high-performance environments.

Ready to get started? Contact us today.

Chromate Conversion Standard

Chromate Conversion Standard

Consolidated Metal Technologies (CMT) Chromate Conversion process adheres to the highest industry standards to ensure quality and consistency:

- MIL-C-5541, Class IA & III: Complies with military specifications for high-performance coatings, available in clear and gold colors.

- MIL-DTL-5541F: Meets the detailed requirements for chemical conversion coatings on aluminum and aluminum alloys.

- ASTM B449: Follows the standards set by ASTM for chromate conversion coatings, ensuring robust corrosion resistance.

Chromate Conversion Capabilities

CMT is equipped with specialized tanks to accommodate diverse Chromate Conversion needs:

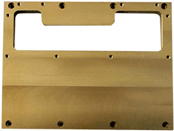

- Clear Chrome Conversion tank: 24″ x 52″ x 24″, suitable for a wide range of parts and components.

- Gold Chrome Conversion tank: 30″ x 70″ x 40″, providing ample space for larger or more complex items.

Other Names for Chromate Conversion

Chromate Conversion is also known as:

- Chem Film

- Chemical Conversion

- Iridite

- Alodine

- Divercoat

- Chromicoat

Chromate Conversion in Round Rock, Texas

Chromate Conversion can be customized to meet specific cosmetic requirements, offering a visually appealing finish when needed. Whether you’re seeking protection against harsh environmental conditions or a coating that ensures electrical continuity, our Chromate Conversion services are engineered for precision and reliability.

At CMT, we deliver Chromate Conversion solutions that provide superior protection for your metal components. With our expertise, you can count on enhanced performance and extended durability, even in the most challenging environments.