About Anodizing at Consolidated Metal Technologies

Anodizing is an electrolytic passivation process that strengthens the natural oxide layer on aluminum surfaces. This treatment significantly enhances corrosion and wear resistance, improving aluminum components’ durability and functionality. Additionally, anodizing elevates the aesthetic appeal of the parts, combining superior performance with a refined appearance.

Benefits of Anodizing

- Increased Corrosion Resistance: The anodic layer forms a robust barrier that shields aluminum from environmental factors, dramatically enhancing its corrosion resistance.

- Enhanced Wear Resistance: The hardened surface minimizes wear and tear, significantly extending the lifespan of aluminum components.

- Aesthetic Versatility: Anodized films offer diverse cosmetic possibilities. Thick porous coatings can absorb dyes, producing vibrant colors, while thin transparent coatings create light interference effects, resulting in a distinctive and unique appearance.

Clear Anodize

Color Anodize

Anodizing Standard

Our anodizing process meets stringent industry standards to ensure the highest quality:

- MIL-A-8625 Type II, Class 1 & 2: Complies with military specifications for anodic coatings, ensuring superior durability and protection.

- ASTM B580: Adheres to the American Society for Testing and Materials standards for anodizing, ensuring consistent and reliable results.

Anodizing Capabilities

We offer Type II anodizing (Sulfuric Acid) with a wide range of options to meet your specific needs:

- Standard colors: We maintain seven standard colors on hand, ensuring quick turnaround times for common requests.

- Custom colors: Custom color options are available upon request to match your exact specifications.

- Tank size: Our largest tank measures 44 in. x 46 in. x 72 in., allowing us to handle both small and large components efficiently.

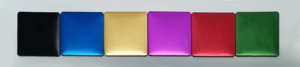

Anodizing Colors Available

We offer a diverse palette of anodizing colors, ensuring your parts not only perform well but also look great:

- Standard colors: Clear, black, blue, gold, purple, red, green.

- Custom colors: Available on request to suit specific design and branding requirements.

Why CMT for Anodizing?

- Quality assurance: Adherence to industry standards ensures that our anodized parts meet the highest quality and performance criteria.

- Customization options: From a wide range of colors to custom specifications, we offer flexibility to meet your exact requirements.

- Advanced facilities: Equipped with state-of-the-art anodizing tanks and equipment, we handle projects of varying sizes and complexities.